National Plastics & Rubber have expanded our trusted wheel chock range to include a NEW ergonomically designed workshop wheel chock. Complementing our range of quality tested mining products, this chock is purpose designed for the workshop environment.

What is the function of a wheel chock?

The function of a wheel chock is to prevent unwanted movement of vehicles by stopping wheels from being able to roll and move. Chocks can also be referred to as wheel stoppers, stop blocks, and tyre wedge.

For more information and to answer the question of “do wheel chocks actually work” – read our blog on NPR’s range wheel chocks and how they can benefit your family car or heavy duty mining truck fleet. Check out our range of light vehicle chocks and other vehicle, including 4WD wheel chocks.

At NPR we are also proud to offer a range of aviation wheel chocks. Our AerochockTM’s are lightweight aircraft wheel chocks suited for narrow and wide body aircrafts. View the range here.

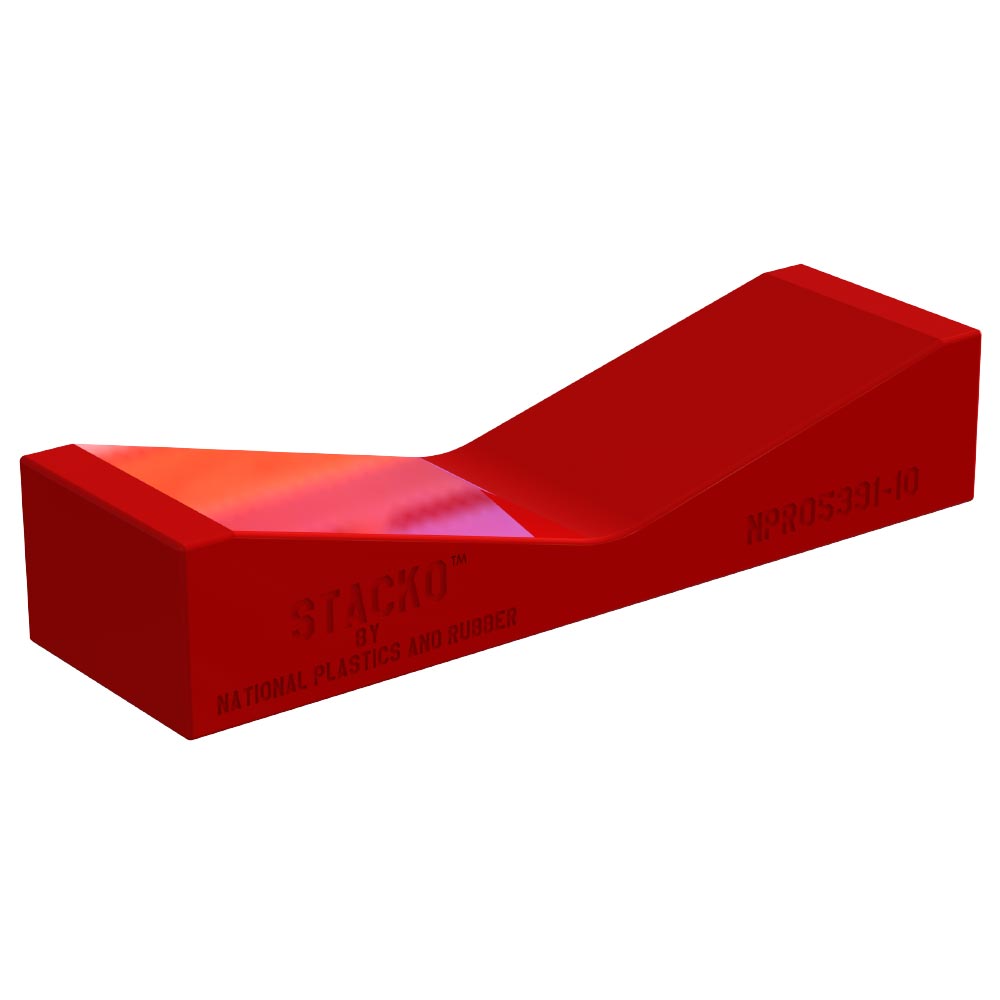

INTRODUCING THE WORKSHOP WHEEL CHOCK – the easily-manoeuvrable, lightweight and durable solution

Designed in conjunction with Anglo Dawson, the workshop chock was created in response to an incident they experienced where a traditional wheel chock was installed incorrectly, driven over, and as a result became a projectile.

As these incidents were occurring in a workshop environment, we a designed a chock better suited to these conditions. Standard wheel chocks are made to secure a truck on a 10% gradient on the mine site, however these conditions are not present in a workshop. As such, the features present on our standard truck chocks could be removed from the workshop chock.

Featuring a handle and wheels, the workshop chock also eliminates numerous WHS risks – including back strain caused by repeat bending and chocking, as well as removing the need to go under the footprint of the truck.

As the workshop chock is not designed to suit extreme gradients, one size chock will suit all trucks – no need to purchase numerous sizes. One workshop chock will can be used all mining trucks, including CAT dump trucks, Komatsu miming trucks to even the biggest mining truck!

WHEN SHOULD YOU CHOCK THE WHEELS?

NPR’s workshop wheel chock can be used in any workshop operations requiring the truck to be secured. During maintenance, for example, it is important to ensure large mining trucks do not have the ability to roll and move.

DO I NEED TO CHOCK BOTH SIDES OF THE WHEEL?

Yes. Both sides of the tyre should be chocked with workshop wheel chocks. This will ensure the truck cannot roll either way.

WHERE SHOULD A WHEEL CHOCK BE PLACED?

Using the handles and wheels, manoeuvre the chock into position, this should be flush against the tyre with the handle against the sidewall. Watch our instructional video for more information.

National Plastics & Rubber’s workshop wheel chock for trucks is the ultimate wheel stopper for the workshop environment – preventing projectile chocks and ergonomically designed – a winner!

For more information or a quote get in contact with us – click here.

To suit mining equipment with a smaller tyre width (such as Graders) check out our Size 4 Workshop Wheel Chock.

;

;

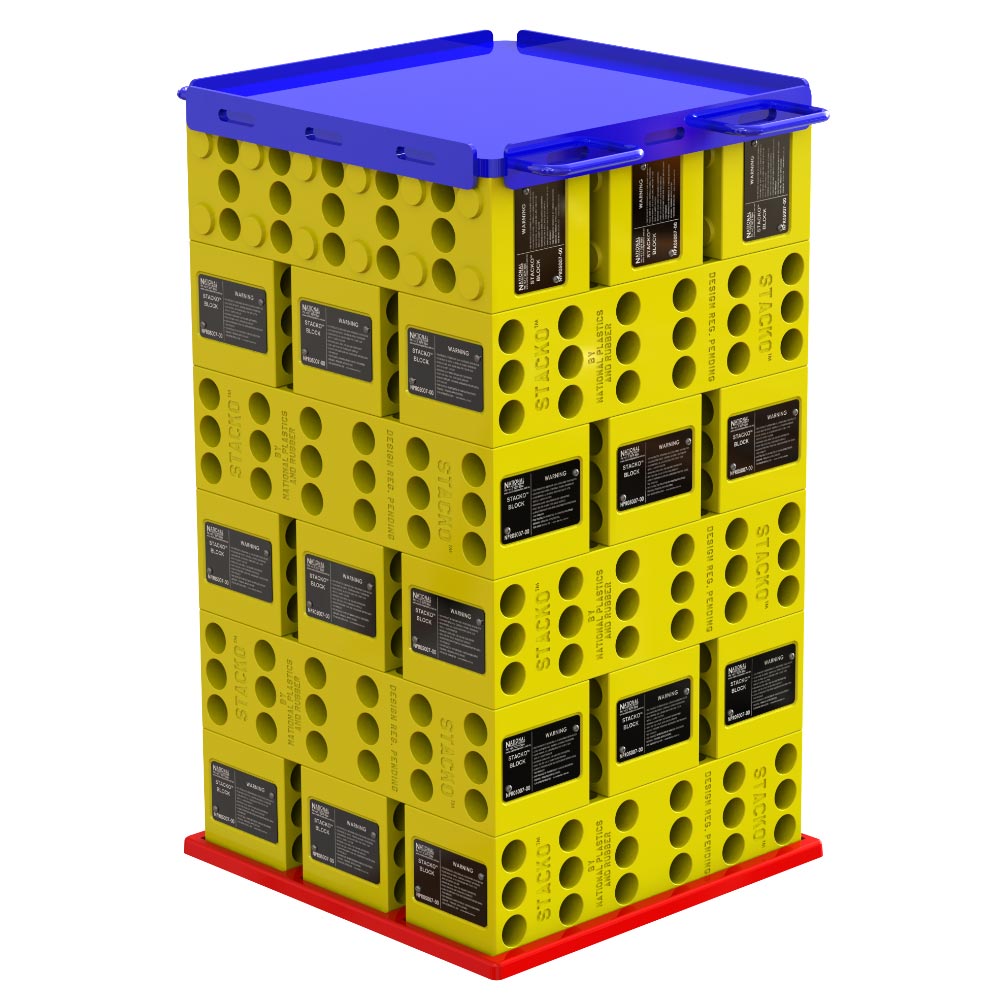

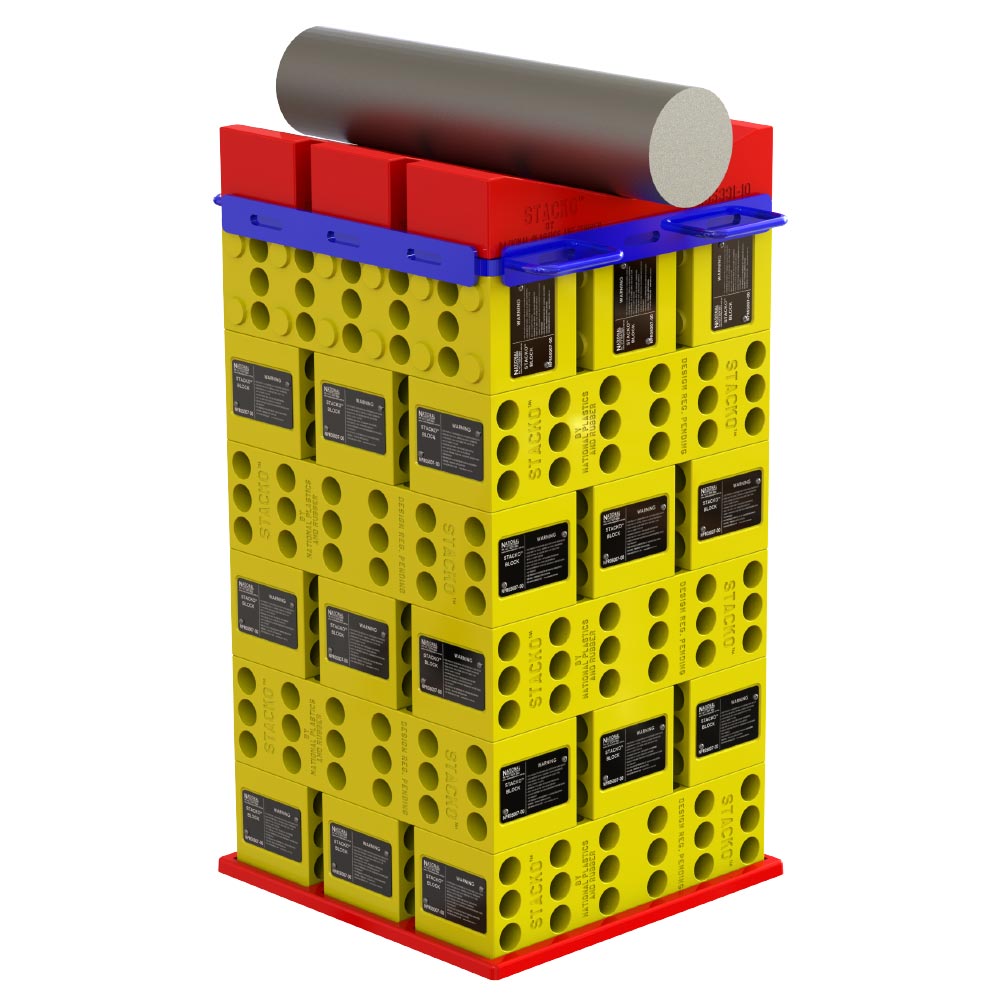

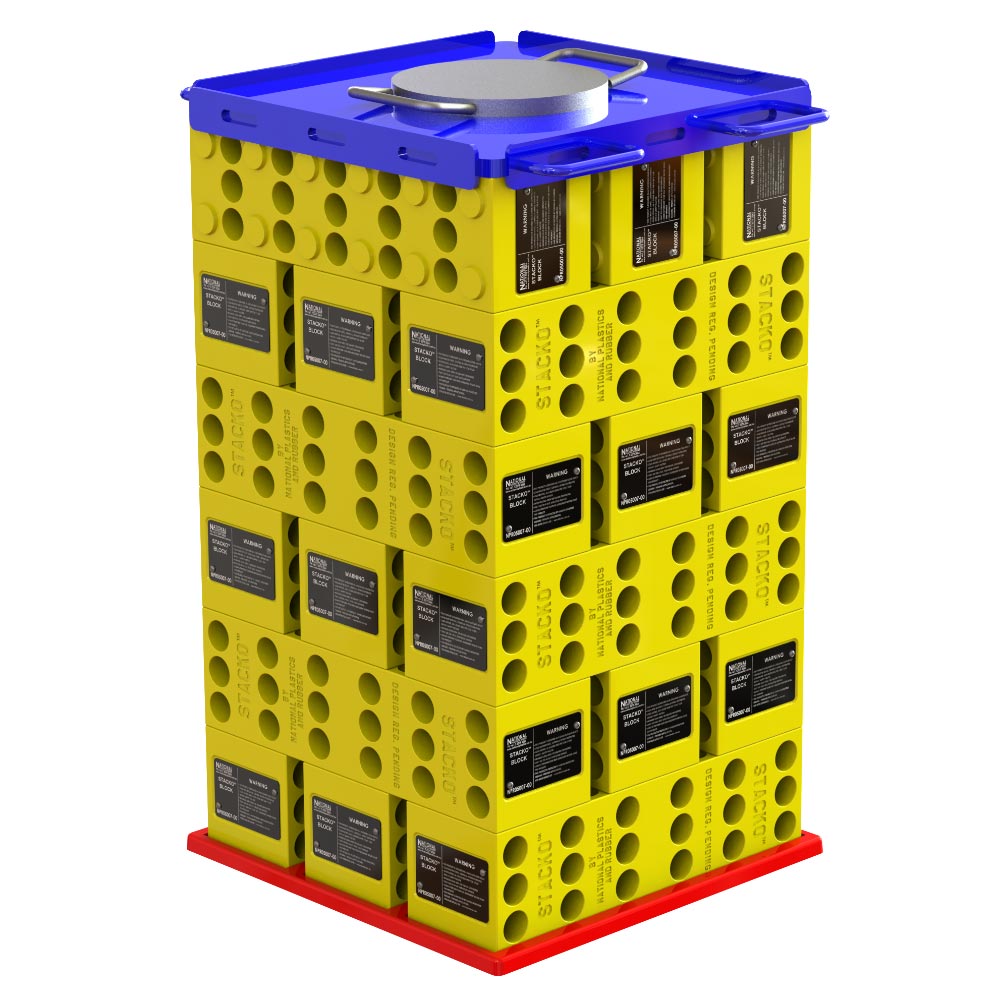

+ THIS PRODUCT IS DESIGNED AS A LOAD SUPPORT BLOCK

+ THIS PRODUCT IS DESIGNED AS A LOAD SUPPORT BLOCK